Shaping Excellence with Precision Aluminium Extrusions

Your trusted partner for world-class profiles across diverse industries.

At Arkane Alusystems, we design and manufacture world-class aluminium extrusion solutions for every industry — from architecture to engineering, transportation to electronics.

Welcome to Arkane Alusystems

We Provide the Best Industrial Aluminium Extrusion Solutions for Your Business.

With over 15 years of expertise in aluminium extrusion manufacturing, Arkane Alusystems stands as a trusted partner for industries that demand precision, strength, and reliability.

Founded in January 2021, Arkane builds on the strong foundation of SP Metals (established in 2009 at Metoda GIDC, Rajkot) — combining technical excellence with modern innovation.

From concept to completion, we deliver custom aluminium extrusion profiles in grades such as 6063, 6061, 6082, and 6005, crafted to meet the highest industry standards and tailored to your exact requirements.

Our state-of-the-art Manufacturing Unit , spread across 87,000+ sq. ft., in-house melting facilities, advanced testing laboratories, and precision extrusion machinery — ensuring every product reflects unmatched quality and consistency.

At Arkane, we believe in more than manufacturing. We believe in engineering possibilities — taking on the toughest design challenges, suggesting the best alloy grades, and delivering extrusion profiles that perform flawlessly in real-world applications.

Our Products

At Arkane, we specialize in manufacturing high-quality best aluminium extrusion profiles tailored for a wide range of industrial and architectural applications. Our expertise allows us to produce precise, durable, and application-specific extrusions with consistent mechanical strength and surface finish.

Every extrusion is tailored with precision, strength, and longevity in mind.

What We Manufacture

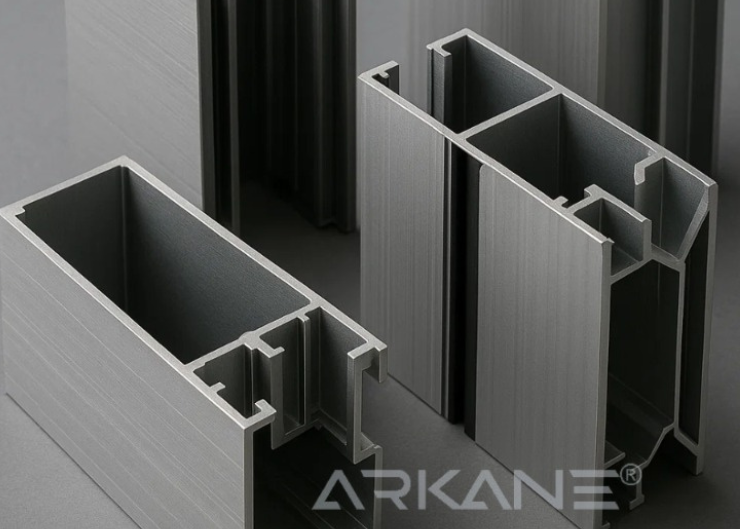

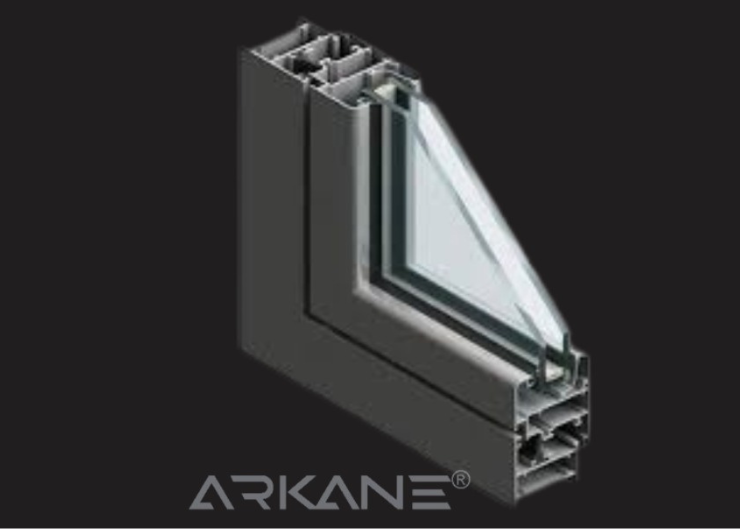

- Aluminium Profiles for Doors and Windows

- System Windows and Door Closures

- Profiles for Kitchen Cabinets

- Electronic Industry Applications such as HEAT SINKS

- Electric Industry Applications such as Bus-Bars

- Profiles for Temporary and Permanent Structures

- Railing Systems and Façade Solutions

- Louvers, Blinds, and Curtain Mounts

- Medical and Hospital Equipment Profiles

- Transport Vehicle Extrusions

- Air Conditioning and HVAC Profiles

- Profiles for Solar Structures

We Are Open For Opportunities!

Arkane Alusystems is trusted by industries across India and globally for our commitment to quality, performance, and customization.

Why Choose Us

We Are Leader In Industiral Market

Arkane Alusystems is trusted by industries across India for our commitment to quality, performance, and customization.

Quality Production

From alloy casting and die design to extrusion and surface finishing, every process is handled within our facility to ensure unmatched quality and faster turnaround. We develop complex and application-specific profiles tailored to your functional, aesthetic, and structural requirements.

Unwavering commitment to timelines, customization, and performance

We maintain strict tolerances, consistent surface finishes, and reliable timelines across every order, whether it’s a single prototype or high-volume production.

Our Process

How We Works

At Arkane Alusystems, we turn your ideas into precision-engineered aluminium profiles through a seamless process — from understanding your requirements and selecting the right alloy to in-house melting, extrusion, and rigorous quality testing — ensuring consistent performance, superior finish, and on-time delivery every time.

Understanding Your Requirement

We start by collaborating closely with our clients to understand their application, technical specifications, and design goals.

Grade Selection & Design Support

Our experienced engineers help you choose the right aluminium alloy and optimize your profile design for strength, weight, and cost efficiency.

In-House Melting & Extrusion

With our integrated melting facility, we produce aluminium billets in various grades — ensuring purity, consistency, and superior mechanical properties.

Precision Manufacturing

Using advanced extrusion technology, we manufacture profiles ranging from 0.6mm to 50mm thickness — meeting global standards for accuracy and surface finish.

Quality Assurance

Every batch undergoes rigorous in-house lab testing for raw materials and finished profiles, guaranteeing durability, strength, and performance.

On-Time Delivery

From small custom batches to bulk orders, our efficient production and logistics systems ensure timely delivery without compromise on quality.

FAQ

Popular Question

Yes, we specialize in developing custom aluminium extrusions based on technical drawings, usage environment, and mechanical needs.

We manufacture profiles in a wide range of grades, including 6063, 6061, 6082, 6005, and 6060 — suited for structural, architectural, and industrial applications.

Our standard minimum order quantity is approximately 300 kg per profile, which may vary based on design complexity and alloy type.

Yes, we provide both anodized and powder-coated finishes along with mill-finish and brushed aluminium options.

Yes, we serve domestic and international clients and offer export-grade packaging and reliable logistics support for global shipping.

Our Product

ARKANE Extrusions – Precision Aluminium Extrusion Dies and Profiles

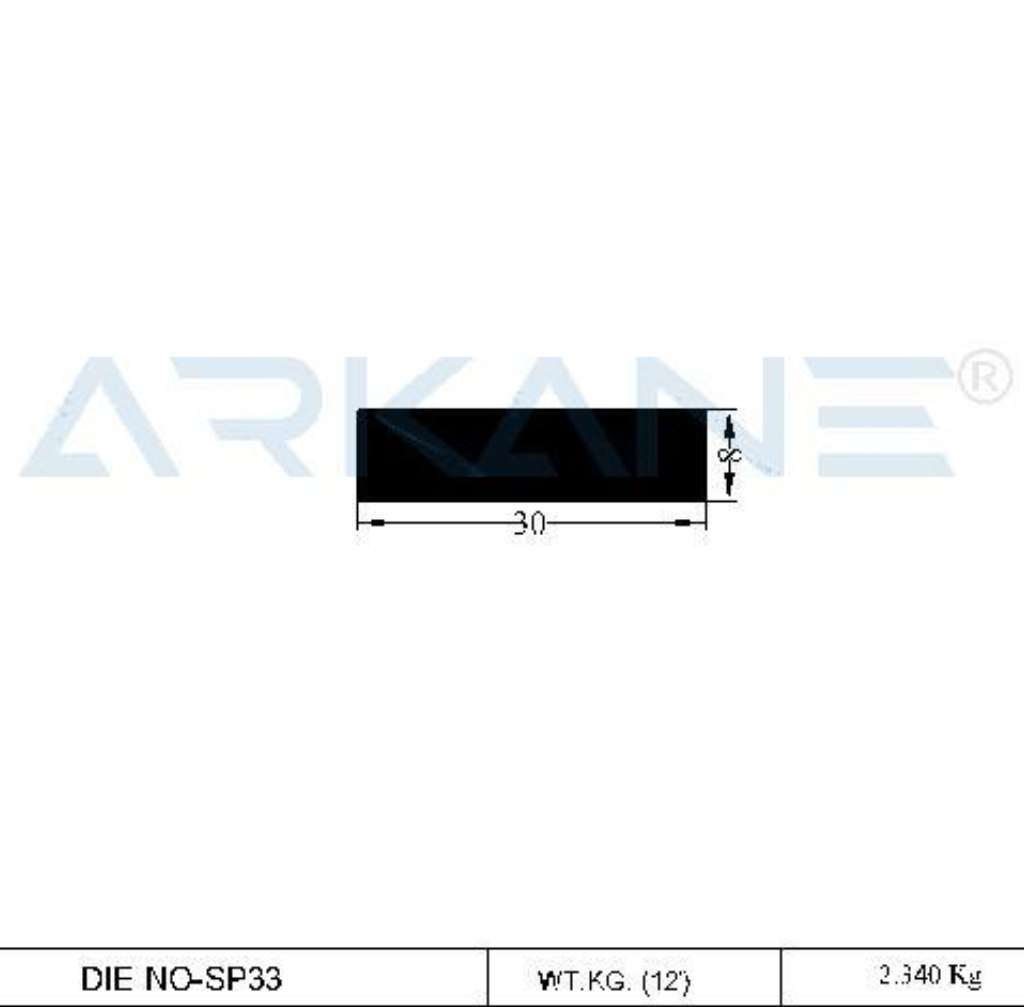

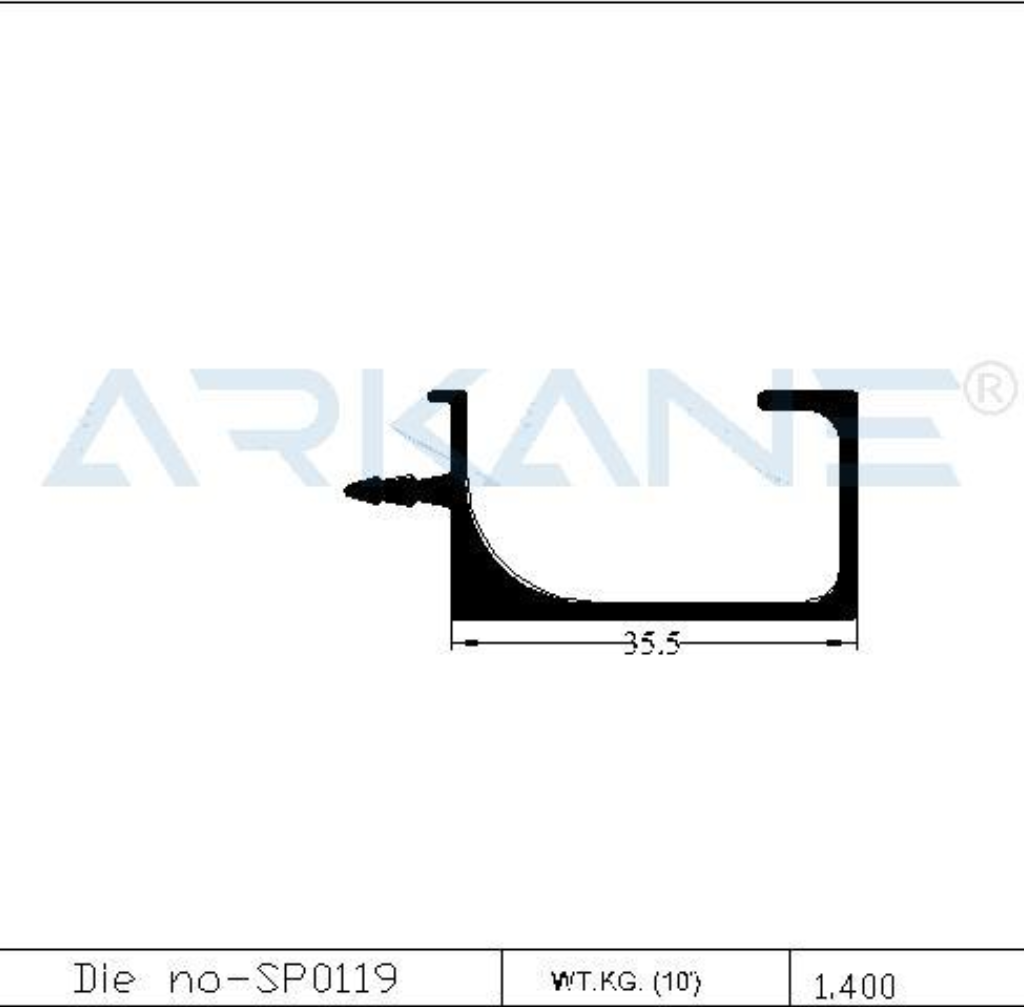

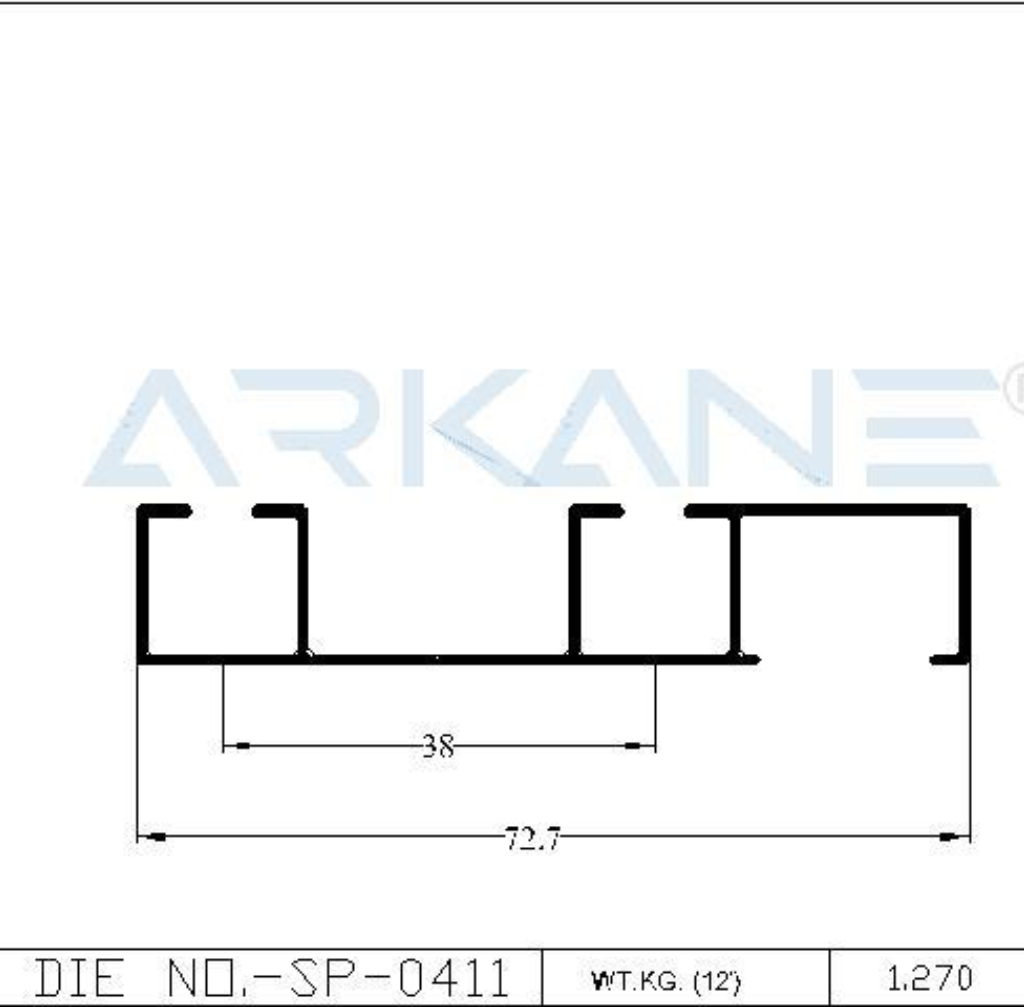

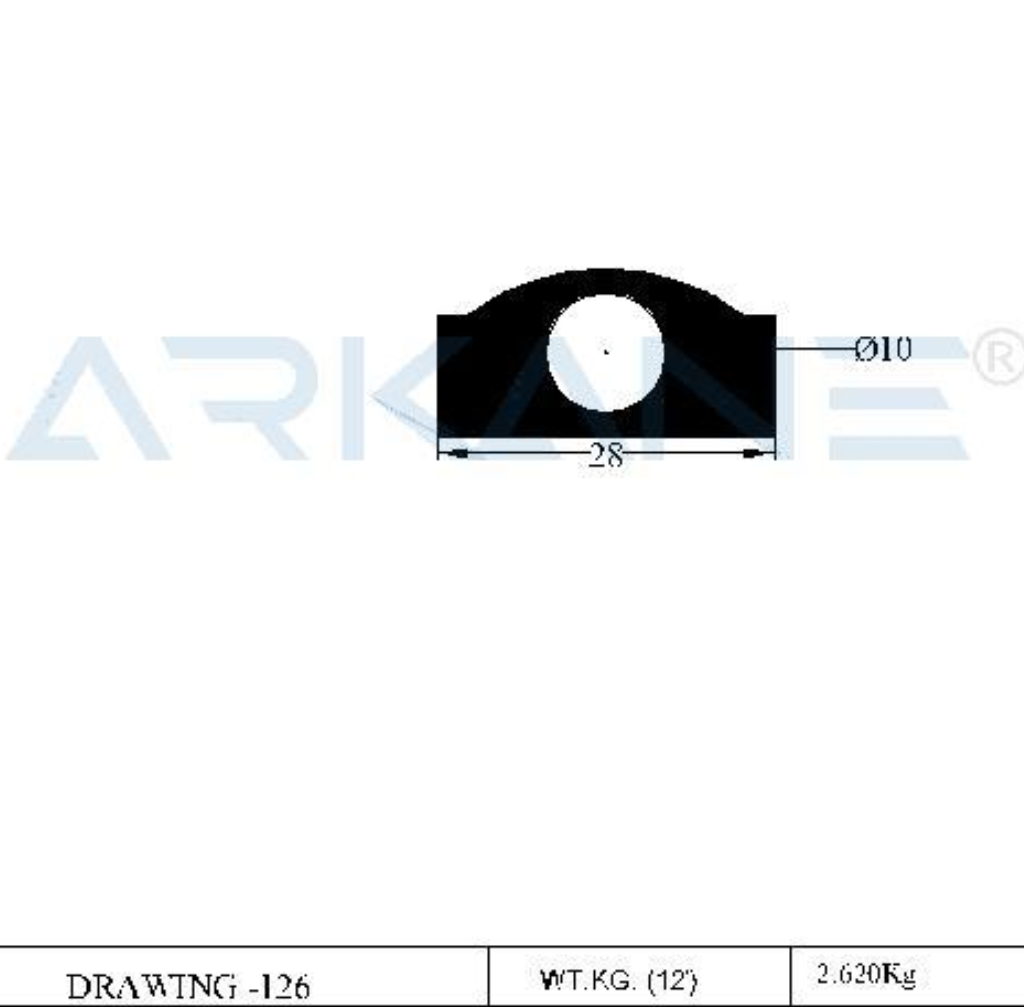

The image is a drawing of an aluminum extrusion die. At ARKANE Extrusions, we specialize in the design and manufacture of premium, high-quality aluminium extrusion dies. We are committed to delivering exceptional tooling solutions for manufacturing units that demand the very best in quality, durability, and performance. Our dies are crafted from superior-grade tool steel (such as H13) and undergo rigorous heat

treatment and finishing processes to ensure optimal operational efficiency and a long service life, capable of producing profiles with tight tolerances and superior surface finishes. Partner with us to elevate your production standards and achieve unparalleled consistency in your aluminium profiles.

Rectangular Solid Bar

Solid rectangular section for structural

support.

Multi-slot Channel

Profile with multiple slots for mounting or

framing.

Wide U Channel

Large U-shaped channel for heavy-duty

applications.

Special Curved Channel

Curved edge channel for specialized

fittings.

Our Aluminium Extrusions Profile Categories

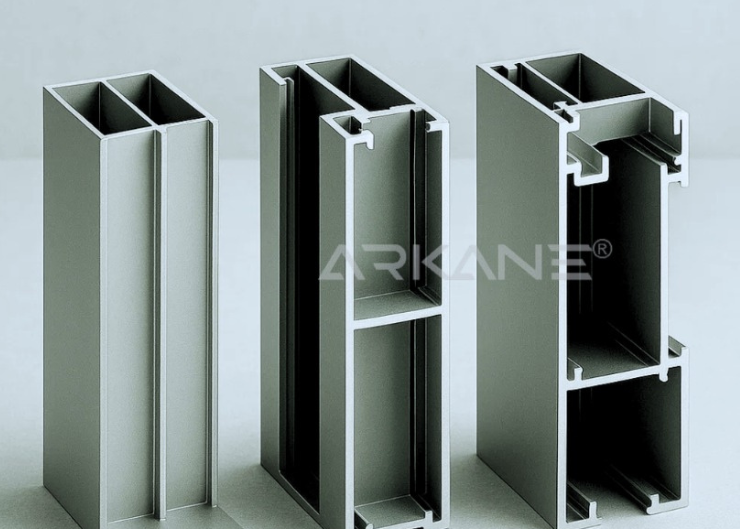

Mastering Complex Aluminium Extrusions

At ARKANE, our expertise covers the full spectrum of aluminum extrusion Profiles, broadly classifying dies into three primary categories based on the profile complexity: Solid, Semi-Hollow, and Hollow Profiles. Solid Profiles are used for simple shapes like bars and angles, which have no enclosed voids. Semi-hollow profiles with partially enclosed cavities, demanding careful engineering to manage metal flow. Hollow Profiles are the most complex, profiles with fully enclosed internal cavities such as tubing or intricate frames, requiring multi-component tooling to ensure precise internal and external dimensions. We provide high-quality, durable solutions across all these categories, tailored to specific manufacturing requirements.

Kitchen Profile

Cabinet Solid Bars

Door And Windows Profiles

Curtain Profile

Solar Roof Top Structures

Glass Railings Profiles

Other Pages

Contact Info

- ARKANE ALUSYSTEMS Sr No 1187 HARIPAR TARAVADA ROAD CHIBHADA LODHIKA RAJKOT 360035 Gujarat

- (+91) 9925722922

Newsletter

Join Our Newsletter for new products updates and offer

Copyright © 2025. All rights reserved @ Arken Alusystem